Every detail counts

In industrial applications, where hygiene is of uppermost priority, every detail counts when it comes to built-in components. Motors used in splash zones have to be built to the standards of hygienic design, ensuring reliability and consumer safety.

Hygienic design incorporates material and geometry choices that result in easy cleanability of the motor components.

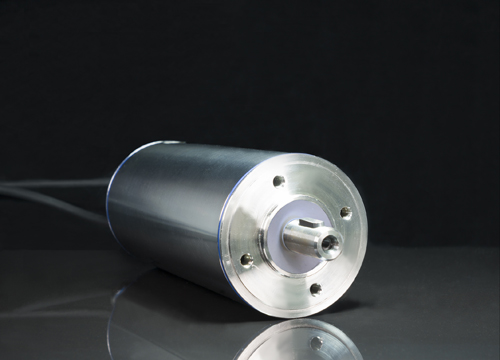

The stainless steel motor encasement plays an important role. It is resistant to corrosion, chemicals, and varying temperatures. Machined stainless steel parts exhibit a particularly smooth surface, reducing the adhesiveness of particles and thus minimizing possible contamination.

Furthermore, the motor has to withstand numerous cleaning cycles. Therefore, it is important that the drive is not damaged or affected by high pressure hot steam cleaning procedures. The encasement must be able to resist the high temperatures and aggressive cleaning agents.

The connections, sealings, and cables have to meet the standards of hygienic design as well. Therefore, cable glands and plugs consist of stainless steel, have smooth surfaces and no hidden openings, reducing particle contamination.

The cables have a particularly resistant coating with an extremely smooth surface that cannot be washed out even by high-pressure washers. The material is resistant against oils, greases, acids and water.