Integrated electronics control functions

The market is increasingly demanding that systems and machines work in a network. This places new demands on drive technology. Rotek developed the three-phase brushless DC drive Romotion to meet these requirements. Available in two versions and with integrated control electronics as standard, the Romotion covers an extended speed range from 400 to 4000 rpm. At 48 V, the motor delivers a continuous output power of 130 W. At its peak, it reaches 200 W. The 24 V version offers an output power of 110 to 130 W.

The actuator can be controlled using analogue and digital voltage signals. It can be easily set, commissioned and its status monitored using a Windows programme. In addition to the inputs for enabling, direction of rotation and speed setting, the electronics offer a serial RS-485 Modbus interface and optional CAN bus. It has a modular design and can easily be expanded with additional functions.

The motor can be operated on a control panel for easy commissioning. Many conventional drive solutions also require sensors built into the motor. The motor control of the Romotion works without sensors. This makes it more compact and less expensive.

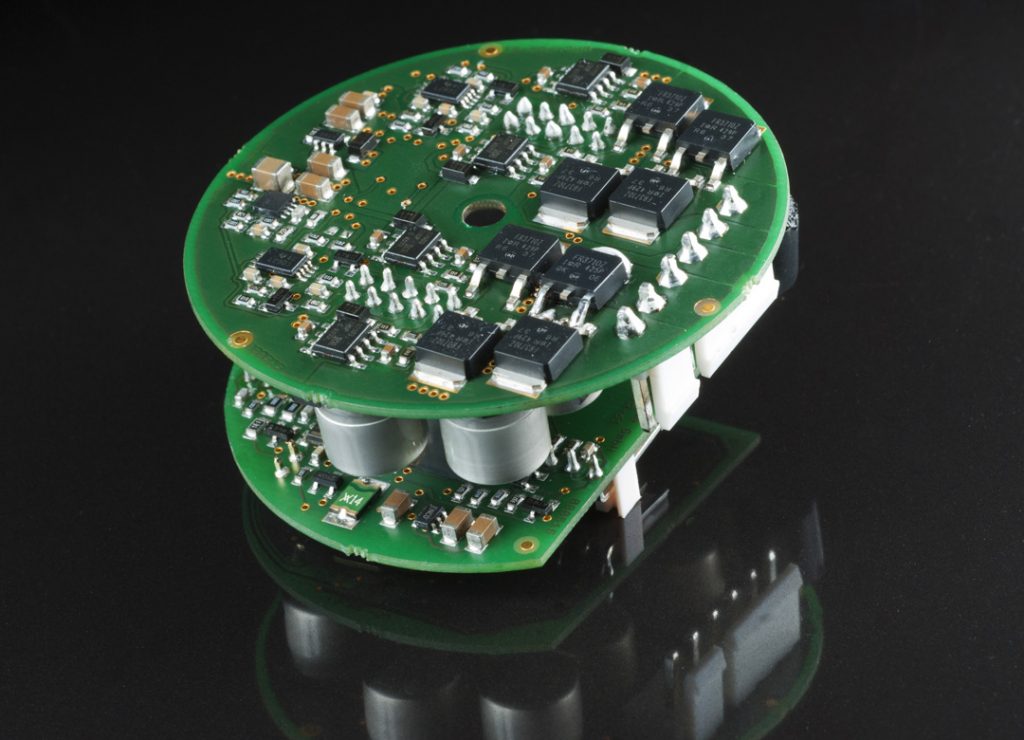

The standard M51 electronics integrated into the Romotion 44 have proven their worth. However, the challenge of procuring older components has prompted us to introduce a new generation together with our electronics partner FW-Systeme: the M52. It not only offers the same excellent function and motor performance as its predecessor, but also impresses with significantly lower manufacturing costs. This will enable us to offer Romotion motors at significantly lower prices in the future.

If applications require maximum precision and accuracy, the internal rotary encoder rotor bearing detection and A/B-I signal is an option. Rotek offers the installation of high-resolution 14-bit rotary sensors for this purpose. These are used for commutation so that the motors can also be operated in a controlled manner in the range below 400 rpm.

In addition to standard settings such as speed ranges, ramps and current limits, users can also customise the PID controller according to their requirements. The Romotion shows its strengths where a variable speed that is largely independent of the torque, low power consumption and a long service life are required. It regulates complex process sequences and communicates with higher-level control systems or even makes them superfluous. It starts up accurately and delivers a high torque as well as good speed control behaviour. It is therefore particularly suitable for use in driverless transport systems, which are becoming increasingly common in warehouse and production logistics.