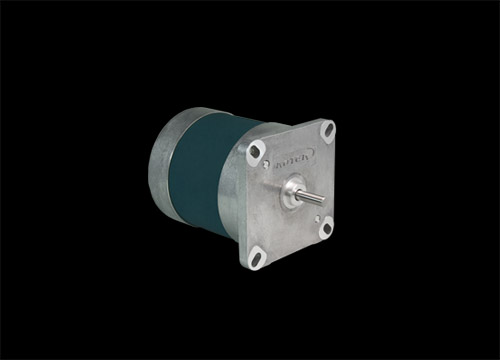

Roslyde motors are our low-noise solution

Resonant frequencies in motorised devices and drive units can hardly be avoided. However, there are applications where they are undesirable. With the Roslyde, Rotek has succeeded in developing a particularly quiet motor that is also popular in noise-critical environments.

Small electric motors are used for a variety of drive tasks. In addition to mechanical quality, smooth running plays an important role. They should work as smoothly and quietly as possible.

Rotek has been manufacturing synchronous motors for many years and offers a modular system with millions of product variants. The advantages of synchronous technology: Thanks to powerful magnetic rotors and efficient coil body winding, synchronous motors are particularly energy-saving and extremely compact compared to conventional capacitor and three-phase motors. They deliver constant speeds regardless of the load and allow starts and stops within fractions of a second. Another typical feature is the self-holding torque, which makes a brake superfluous.

Otherwise often an advantage, this is a disadvantage when it comes to noise development. This is because the magnetic "engagement" of the rotor poles in the stator teeth generates torsional vibrations that are noticeable as structure-borne noise.

Disturbing noises

Now, what people perceive as annoying or loud varies greatly from person to person. Among other things, the frequency and time behaviour of the sound determine whether it is perceived as pleasant or unpleasant. Certain frequencies also appear louder than they actually are. Therefore, the indication of the pure sound pressure/volume level in dB is only of very limited significance. This is because sound pressure is only one aspect of perception. High, shrill sounds such as whistling and squeaking are unpleasant. Sound events with inharmonic frequencies are also disturbing.

Gentle whirring desired

Low, harsh sounds such as scraping and humming are also rated negatively, while a pleasant sound or one that matches the product reinforces expectations of its properties or creates a positive perception. For electric motors, even noises without strong frequency fluctuations are ideal, in which the high and low frequencies are not too dominant and individual sounds are not too prominent. The aim is to achieve a whirring sound that is as gentle, even and barely audible as possible.

Our first starting point was to minimise noise from the motor itself. The alternating magnetic field circulating in the stator winding causes the drive to vibrate. We were able to minimise this effect by specifically optimising the winding technology. At the same time, the usual cogging torque for synchronous motors was minimised by adjusting the design of the magnetic rotor. As the rotor is ground between two centres, it is already so well balanced that no further work is necessary. Unwanted noise can also be caused by the bearings. The more precise they are, the better.

SmoothDrive Technology

As Rotek always uses high-quality ball bearings with special lubrication, no modifications are necessary in the area of the engine mounts. And attention is paid to symmetrical bearings in the particularly precise machining of the end shields. Because the extremely smooth-running Roslyde motor runs so quietly and gently, its design has been christened SmoothDrive Technology.