Advantages of classic synchronous motors

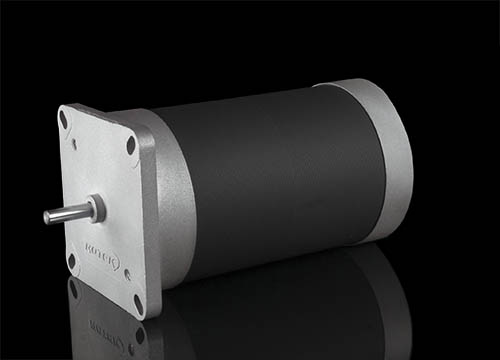

A wide range of in-house drive solutions and customised products are part of Rotek's daily business. They are all based on the synchronous motors of the Rotek modular system. All motors have a diameter of 65 mm and the same external design. This means that they can be combined with any component from this modular system.

Robase motors are our classic synchronous motors. They combine all the advantages of synchronous technology. Due to their design, there are no losses in synchronous motors in the permanent-magnet, conductorless rotor. They therefore have a higher efficiency and lower energy consumption than asynchronous motors with the same power - and in a smaller installation space.

They deliver constant speeds regardless of the load and allow starts and stops within fractions of a second. When de-energised, the rotor magnets hold on to the pronounced stator teeth. A mechanical brake, which is subject to wear and costs installation space, is not necessary. Robase motors are available with four poles (1500 rpm) or six poles (1000 rpm).

The proven technology and its advantages are predestined for certain applications. Synchronous motors are primarily used where a high level of accuracy and synchronisation is required in the motion sequence of different axes and a constant drive speed, e.g. in printing or textile machines and conveyor systems.

Thanks to their compact design, they are also a good solution for confined spaces in machines and systems. In positioning operation, their constant speed, independent of frequency and load, and their dynamic response and braking behaviour are particularly important. And they have a long service life. They can eliminate the need for a brake in many applications. They run reliably in pellet heating systems and actuators and Rotek has sold over a million of them to date