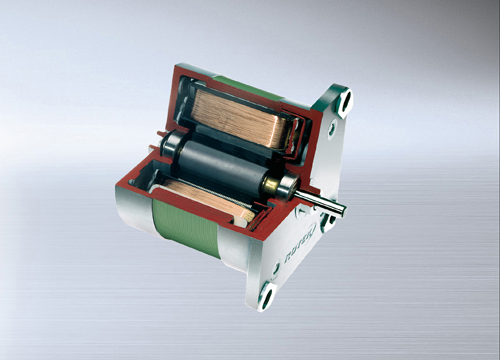

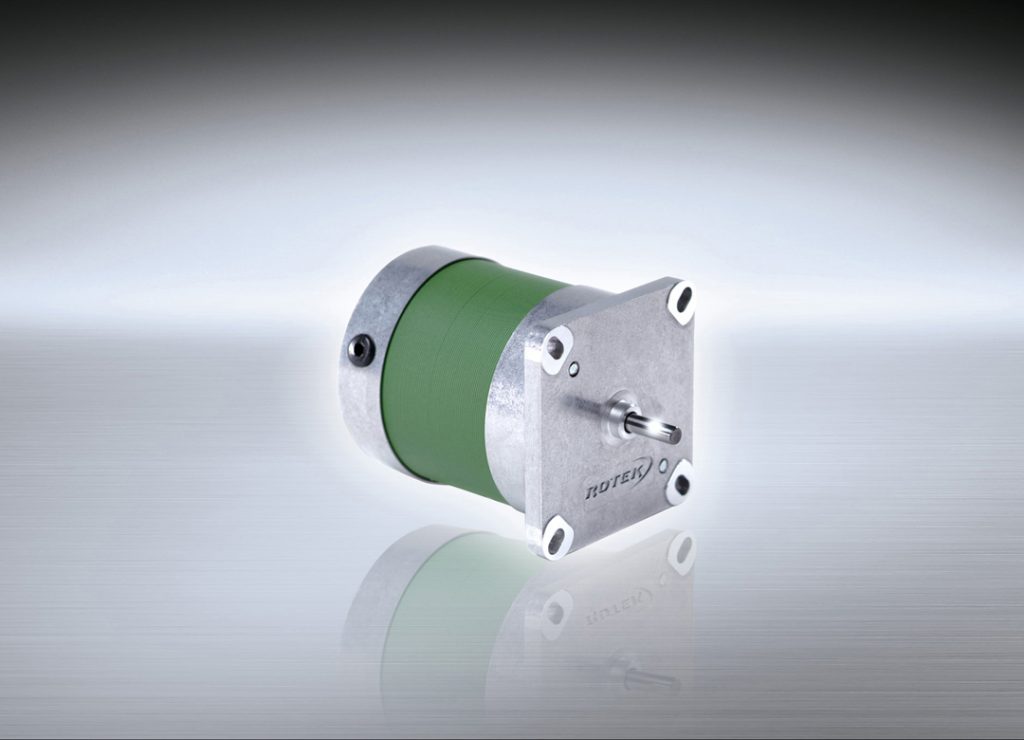

Bremerhaven, November 2008 - The ROSYNC is the first energy-saving micromotor for industrial applications. Ready for series production in January 2008, the KM65/42-4 from the new ROSYNC series from Bremerhaven-based manufacturer ROTEK impresses with its exceptional efficiency. This is made possible by an innovative, patent-pending stator geometry in conjunction with an optimised rotor and modern magnetic materials. ROTEK calls this new technology GreenDrive Technology, which combines low power consumption and low material usage thanks to an extremely compact design. This also has a positive effect on manufacturing costs.

This has increased efficiency to over 70 per cent. Asynchronous motors with the same output are around 50 per cent. In addition, the output power of the ROSYNC series has been increased by around 40 per cent compared to the current SM65 series, which allows for even more compact drive solutions than before. Depending on the winding design, 20-30 watts are possible for the single-phase motors

The three-phase version even offers an impressive 50 watts in continuous operation with an efficiency of over 90 per cent. This efficiency is otherwise only achieved by standard motors in the kW range. The ROSYNC motors have a constant speed regardless of the load, are maintenance-free and also allow frequency inverter operation from 30-2100 rpm. Smooth running was also important to the developers. The motors were originally developed specifically for the pellet heating market. This is because a slight humming noise from the motor can have a negative impact on the well-being of pellet stoves installed in the living room.

The motors are also suitable for many other applications where disruptive motor noise is undesirable. The ROSYNC motors have the same external design as all previous ROTEK motors, so that as many components as possible from the ROTEK modular system can be used. All previous gearbox types can also be fitted. The motors are available in voltages from 1~24 V to 1~230 V as well as 3~230 V for inverter operation and 3~400 V. ROTEK manufactures versions for special voltages and increased output power in short operation according to customer requirements.

About Rotek:

Rotek GmbH & Co. KG was founded in 2000 and took over the business area of Hasselbach & Kausch Elektrokleinmotoren GmbH in Bremerhaven, which was founded on 10 July 1984 by Paul Hasselbach and Hans-Werner Kausch. The company is managed by three partners. Dipl.-Ök. Rolf Treusch is responsible for the commercial area, Dipl.-Ing. Klaus Treusch is responsible for design, production and quality assurance and Prof. Dipl.-Ing. Wilfried Treusch is head of development.

The family-owned company specialises in the production of geared motors in small and medium-sized series. Precision motors from Rotek are used in equipment and apparatus engineering, mechanical engineering, heating technology and intralogistics. The Bremerhaven-based motor manufacturer has developed into a global specialist for customised drive solutions with a long service life. In February 2010, the company won the "preis umwelt unternehmen: nordwest" award for its Rosync energy-saving motor. In 2016, the intelligent drives in the Romotion series were honoured with the bronze medal at the Schütting Prize, the most important innovation competition in the state of Bremen.