Every detail counts

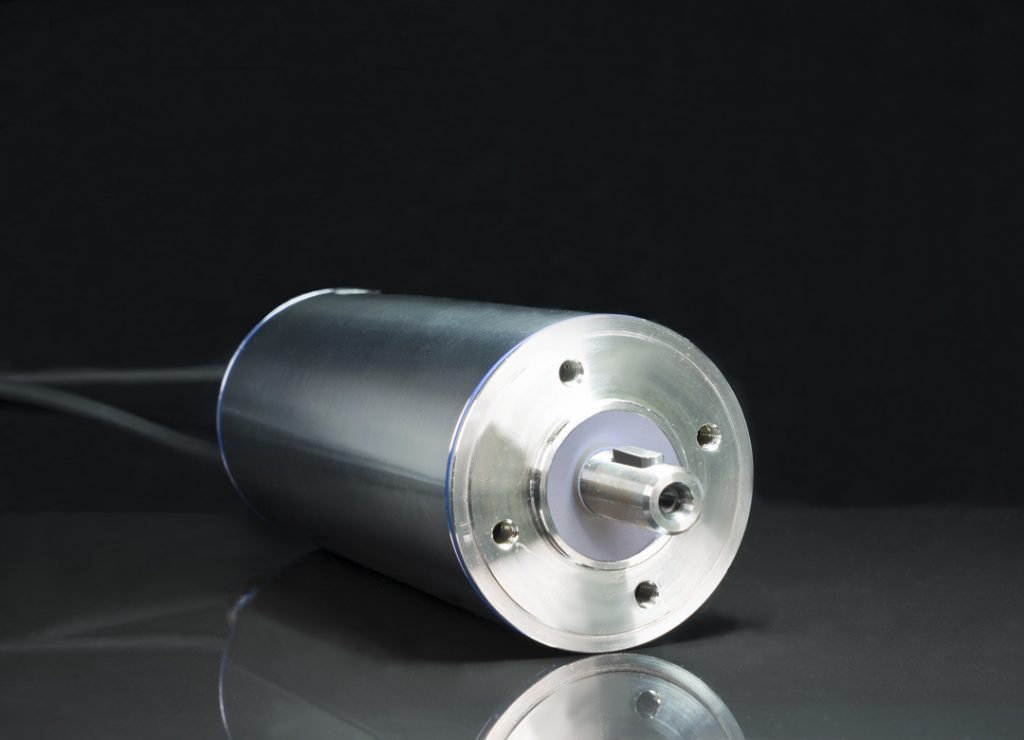

In industries where hygiene is paramount, every detail counts, even when it comes to installed components. If drives are used in the spray zone, they must be designed in accordance with hygienic design. High hygiene standards ensure reliability and consumer safety.

This means that the drive units must be easy to clean and their geometry must be able to withstand soiling.

Stainless steel plays an important role. It is resistant to corrosion, chemicals and temperature. A smooth surface made of 1.4404 stainless steel ensures that no impurities adhere to it.

The drive must be able to withstand many cleaning cycles. It is therefore important that high-pressure cleaning with hot steam and high temperatures does not cause any damage and that aggressive cleaning agents cannot harm the drive.

This means that the drive units must be easy to clean and their geometry must be able to withstand soiling.

Stainless steel plays an important role. It is resistant to corrosion, chemicals and temperature. A smooth surface made of 1.4404 stainless steel ensures that no impurities adhere to it.

The drive must be able to withstand many cleaning cycles. It is therefore important that high-pressure cleaning with hot steam and high temperatures does not cause any damage and that aggressive cleaning agents cannot harm the drive.