Rosync combines smooth running with excellent efficiency

The more expensive energy becomes, the more the focus shifts to using it sparingly. In Germany alone, the use of more efficient drive solutions could save over eight TWh of electricity per year for an assumed 100 million household appliances with small motors. In industry, most of the drives used are small motors, and there is still huge potential for savings here.

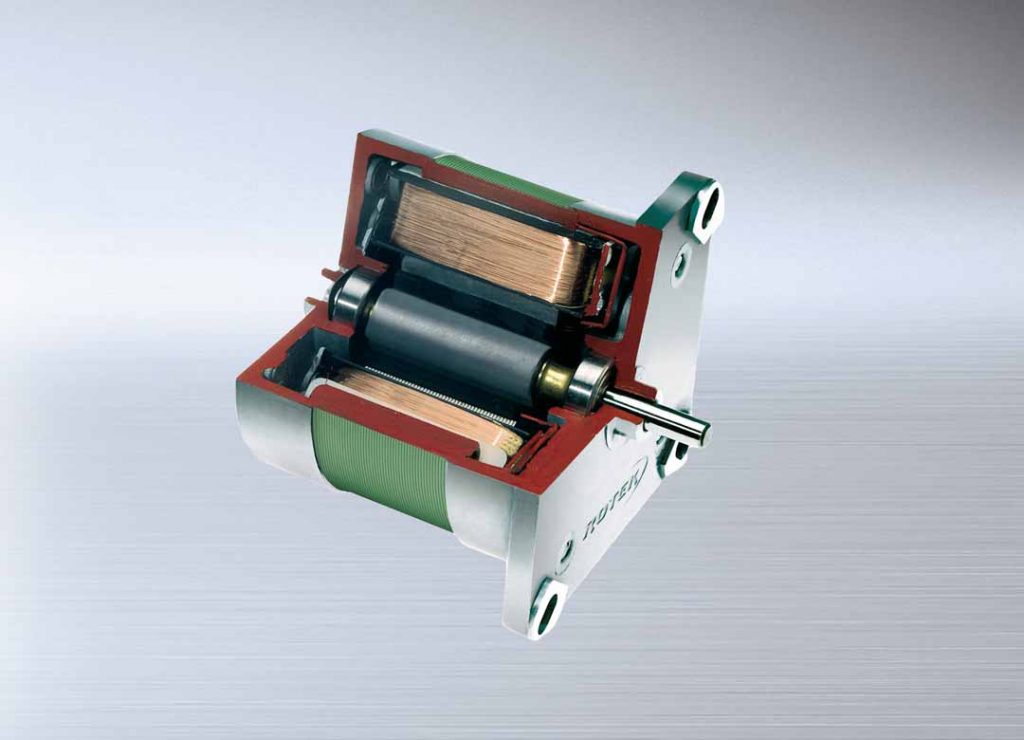

Synchronous motors are already more efficient than asynchronous motors due to their operating principle, as the use of permanent magnets means that no energy is required to generate the magnetic field in the rotor system. But that is not what makes the ROSYNC so special. The developers achieved the outstanding efficiency through new materials and a special stator design. During development, the self-holding torque in the de-energised state was greatly reduced in favour of smooth running. Further advantages are the constant speed (independent of load and voltage), short start and stop times, low-vibration running and a compact design for limited space conditions. Because the better the efficiency, the smaller you can build.

Assuming an electricity price of €0.23*, the results are as follows:

| Rosync | Asynchronous motor | Remarks | |

| Output power in W | 50 | 50 | |

| Efficiency | 90% | 55% | |

| Power consumption in W | 55 | 90 | |

| Duty cycle per year | 8000 hrs. | 8000 | Three-shift operation |

| Energy consumption per year in kWh | 440 | 720 | Power consumption x hours / 1000 |

| Energy savings per year in kWh | 280 | ||

| Electricity costs per year in kWh | 101 € | 165 € | Electricity price € 0.23 |

| Cost savings in 12 years | 750 € |

Compared to conventional synchronous motors, the output power of the ROSYC is between +40 and +200 per cent for the same size. Its behaviour on the frequency converter is also outstanding thanks to its practically resonance-free operation from 1 - 70 Hz. Thanks to its compact design, it not only saves energy but also material. It is also maintenance-free and has a long service life. This solves several customer requirements at once. They save space and energy. They transmit a high torque. And they maintain safety.

Thanks to the design, which is consistently focussed on material efficiency, the acquisition costs are at the usual market level for European quality motors. With an assumed service life of 12 years, the life cycle costs of a Rosync motor are more than a third lower than those of an asynchronous motor of comparable performance. Thanks to the design, which is consistently focussed on material efficiency, the acquisition costs are at the usual market level for European quality motors. With an assumed service life of 12 years, the life cycle costs of a Rosync motor are more than a third lower than those of an asynchronous motor of comparable performance.

The savings effect is particularly evident in applications with longer duty cycles, such as the conveyor belts mentioned above, screw conveyors in pellet heating systems or as drives in rotary heat exchangers. For example, replacing just 100 small motors in operation with motors from the Rosync series can reduce electricity costs by around 6000 euros every year, depending on the electricity price.

The Rosync also demonstrates in an exemplary manner how climate-damaging CO2 emissions can be reduced through consistent product design. The use of a single three-phase motor with an output of 50 watts avoids up to 150 kg of CO2 compared to a conventional motor of the same power. That is 200 times its own weight.

This is an important argument when it comes to taking a holistic view of systems and a company's carbon footprint.