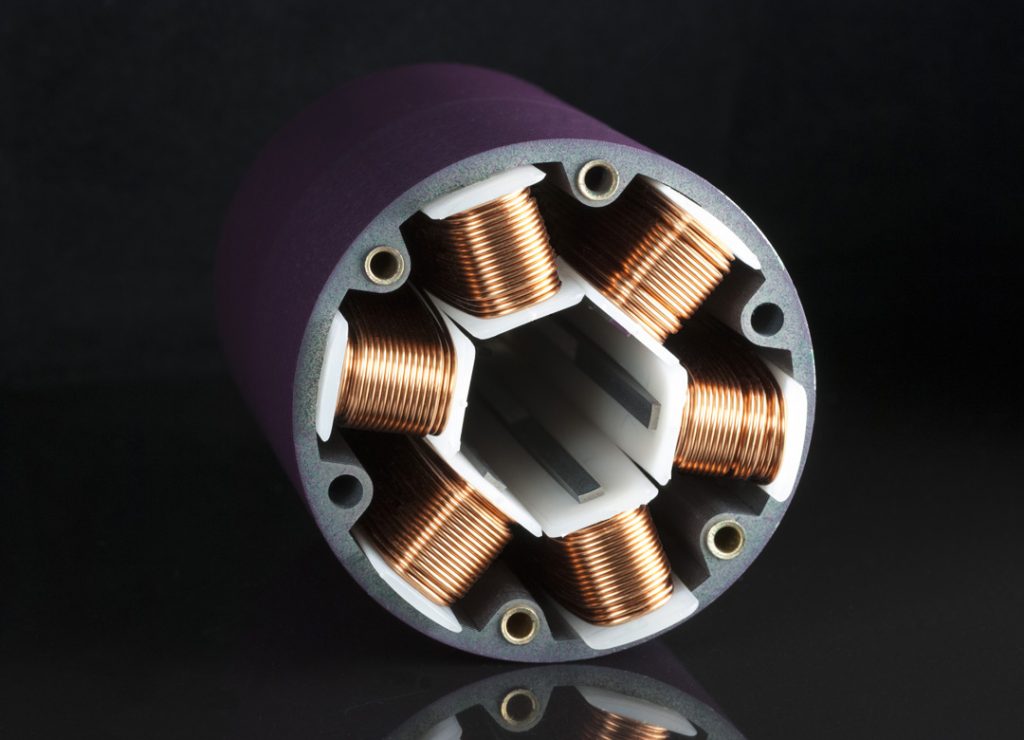

Bremerhaven, November 2017 - At this year's SPS IPC Drives, Rotek is presenting its larger version from the Romotion BLDC motor series. It is significantly more powerful than the smaller version and covers an extended speed range of 400 to 4000 rpm in the sensorless standard version. At 48 V, the motor delivers a continuous output power of 130 W. At its peak, it reaches 200 W. The 24 V version offers an output power of 110 to 130 W.

A new generation of control electronics is also integrated into the drive. In addition to the standard inputs for enabling, direction of rotation and speed setting, it offers a serial RS-485 interface. This works according to the ModBus protocol and is also used for parameterisation. Error and brake chopper outputs are also integrated. As an option, it is possible to place the control unit externally, especially if higher temperature ranges need to be covered. The electronics have a modular design and can be easily expanded to include additional functions. A plug-in board makes the drive CAN bus-capable, for example. In addition, three unassigned digital inputs/outputs are available, which can be used depending on the application, e.g. for connecting limit switches or the optional rotor position detection. For this purpose, Rotek offers the installation of Hall sensors or a high-resolution 14-bit rotary sensor. This means that the motors can also be operated in the range below 400 rpm. New is a low-cost electronic unit for the Romotion. It is the low-cost solution for simple tasks, e.g. in rotary heat exchangers.

For use in customised applications with multiple drives, the motors can also be networked directly via the bus. In this case, one drive operates in master mode and the others as slaves. The free connections can then be used as signalling inputs and outputs. In this way, complex processes can be realised without separate electronic control.

In the download area of the website, Rotek offers the latest version of the MotorManager parameterisation software with an extended range of functions. In addition to standard settings such as speed ranges, ramps and current limits, users can now also customise the PID controller according to their requirements. A very interesting feature is the output of motor data such as current consumption and speed to a connected computer. This makes it possible to immediately recognise how heavily the motor is loaded and whether the drive is correctly dimensioned. The data can be output either as a diagram or as a table. For easy commissioning, the drive can be operated on a control panel.

On request, the motor is available with the drive-integrated safety function STO (safe torque cut-off). It ensures that a switched-off motor can no longer safely generate torque. In accordance with stop category 0 of EN 60204, the power supply is interrupted immediately and the drive coasts to a torque-free stop. Maintenance work, for example, can then be carried out without any danger. Monitoring the status reliably prevents the motor from restarting unintentionally. Compared to other external safety components, this function has the advantage of requiring less installation and wiring work. It operates wear-free and faster reaction times are possible.

The Romotion shows its strengths particularly where variable speed, independent of torque, low power consumption and a long service life are required. Its adaptability allows it to handle even complex drive tasks. Its low-vibration running behaviour makes it ideal for use in noise-sensitive environments. With the same external design as the other Rotek motors, the Romotion BLDC motor fits all components from the Rotek modular system. In addition to the proven planetary gearboxes, Rotek also offers the motor with worm gearboxes. A combination with robust parallel shaft gearboxes is also possible. Rotek also supplies mechanical customisations in smaller quantities according to customer requirements.

About Rotek:

Rotek GmbH & Co. KG was founded in 2000 and took over the business area of Hasselbach & Kausch Elektrokleinmotoren GmbH in Bremerhaven, which was founded on 10 July 1984 by Paul Hasselbach and Hans-Werner Kausch. The company is managed by three partners. Dipl.-Ök. Rolf Treusch is responsible for the commercial area, Dipl.-Ing. Klaus Treusch is responsible for design, production and quality assurance and Prof. Dipl.-Ing. Wilfried Treusch is head of development.

The family-owned company specialises in the production of geared motors in small and medium-sized series. Precision motors from Rotek are used in equipment and apparatus engineering, mechanical engineering, heating technology and intralogistics. The Bremerhaven-based motor manufacturer has developed into a global specialist for customised drive solutions with a long service life. In February 2010, the company won the "preis umwelt unternehmen: nordwest" award for its Rosync energy-saving motor. In 2016, the intelligent drives in the Romotion series were honoured with the bronze medal at the Schütting Prize, the most important innovation competition in the state of Bremen.