Bremerhaven, November 2019 - At this year's SPS -smart production solutions in Nuremberg, Rotek is presenting its new Rotect motor series in hygienic design.

The new stainless steel motors in the Rotect series provide optimum protection in highly corrosive and harsh environmental conditions and are particularly suitable for processes that require a high level of hygienic safety. They are the right choice wherever it is important that dirt and bacteria cannot gain a foothold and aggressive cleaning agents or hot steam are used.

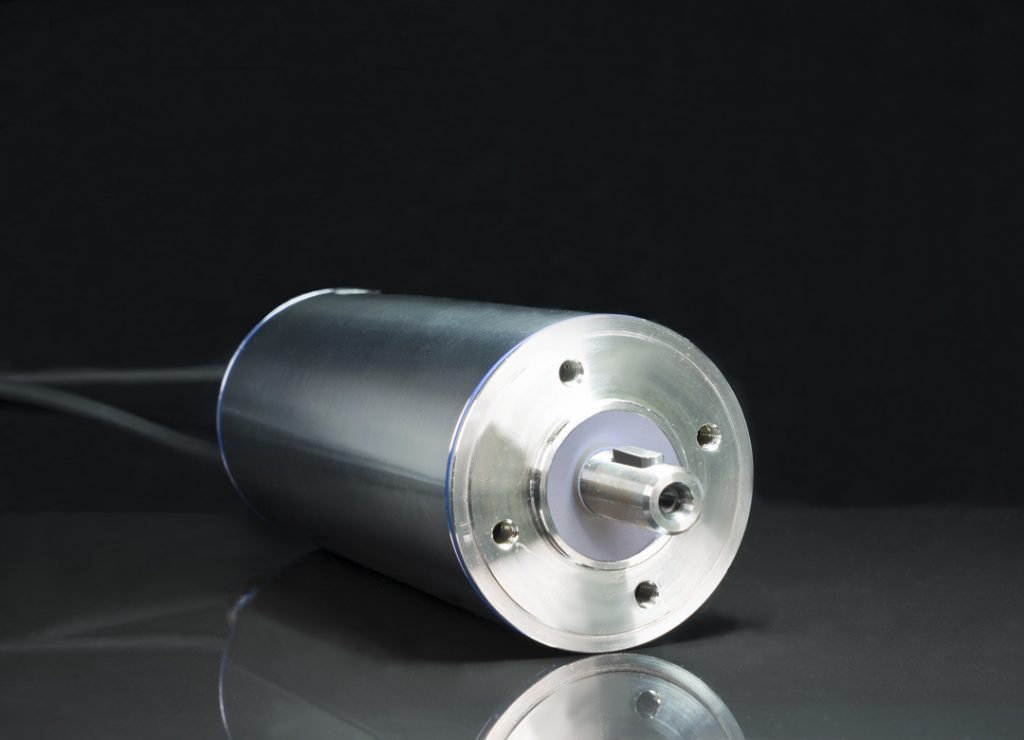

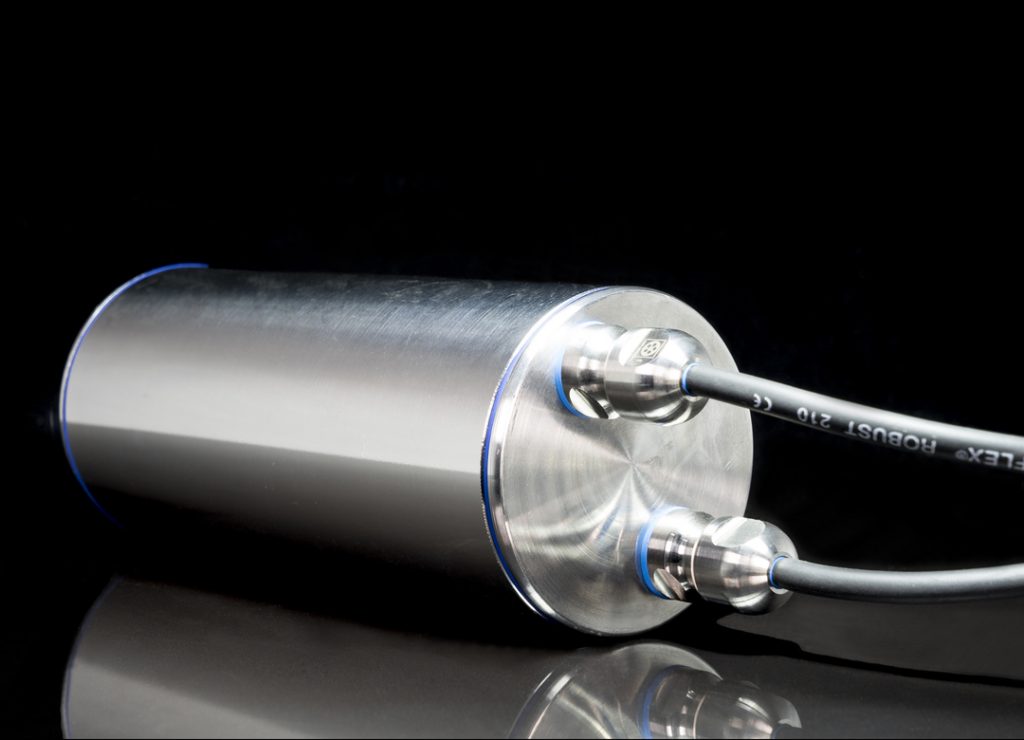

Encapsulated in a housing made of stainless steel 1.4404, the design of which is characterised by particularly smooth surfaces and the consistent avoidance of dirt pockets, they meet the highest hygienic requirements. Manufactured in protection class IP68 10 bar, they are also suitable for high-pressure cleaning. A version with IP69k protection is currently in preparation.

The new Rotect drives offer maximum flexibility in the choice of motor technology. They can be supplied as AC or three-phase motors or as BLDC drives with peak outputs of up to 200 W. This allows the user to utilise the special advantages of Robase, Rosync, Roslyde or Romotion motors in environments that require a hygienic design. High-performance drives are available in conjunction with the integrated planetary gearboxes with permissible peak torques of 75 Nm.

In industries where hygiene is the top priority, every detail counts, even with installed components. Rotek supplies Rotect motors with the appropriate resistant cables and corresponding connectors or cable glands, depending on customer requirements and application.

Rotek wants to win new customers from the food industry, beverage production, chemical and pharmaceutical industries and the offshore sector with the Rotect drives.

About Rotek:

Rotek GmbH & Co. KG was founded in 2000 and took over the business area of Hasselbach & Kausch Elektrokleinmotoren GmbH in Bremerhaven, which was founded on 10 July 1984 by Paul Hasselbach and Hans-Werner Kausch. The company is managed by three partners. Dipl.-Ök. Rolf Treusch is responsible for the commercial area, Dipl.-Ing. Klaus Treusch is responsible for design, production and quality assurance and Prof. Dipl.-Ing. Wilfried Treusch is head of development.

The family-owned company specialises in the production of geared motors in small and medium-sized series. Precision motors from Rotek are used in equipment and apparatus engineering, mechanical engineering, heating technology and intralogistics. The Bremerhaven-based motor manufacturer has developed into a global specialist for customised drive solutions with a long service life. In February 2010, the company won the "preis umwelt unternehmen: nordwest" award for its Rosync energy-saving motor. In 2016, the intelligent drives in the Romotion series were honoured with the bronze medal at the Schütting Prize, the most important innovation competition in the state of Bremen.