Substitutes Berger Lahr Motors

Schneider Electric will stop production of the well-known Berger Lahr synchronous motors in the RSM 828 to 884 series because the main focal points of the company have changed. These motors are used, for example, in measurement and control technology as actuators for valves and dampers, in apparatus and equipment engineering, in label dispensers and analytical instruments, in access systems and supermarket display cabinets or in metering pumps.

ROTEK can deliver substitute

The good news: we have the right solutions for customers looking for a virtually identical substitute. The Robase series motors correspond to the Berger Lahr RSM series but have a slightly higher power output.

The frequency version available with the Berger Lahr motor with the same capacitor for operation at 50 or 60 Hz is available as standard with the Robase. The Robase is available for all common nominal voltages. Robase motors are available with four poles (1500 rpm) or six poles (1000 rpm), with wires or a terminal box and with an IP40 or IP55 rating. All motors are designed as standard for continuous operation. Special windings for increased power output in short-term operation are available on request..

As a result of the consistent integration in the modular system, the customer can replace motors previously used, for example from Berger Lahr, with the Rosync without taking any constructive measures and save energy at the same time. Or, if a drive is used for exceptionally noise-critical applications, with the especially smooth running Roslyde motors.

simple replacement

Following Robase models substitute the Berger Lahr motors:

828/3 = Robase 36

842/3 = Robase 46

856/3 = Robase 66

884/3 = Robase 86

the matching spur gear drive G and W

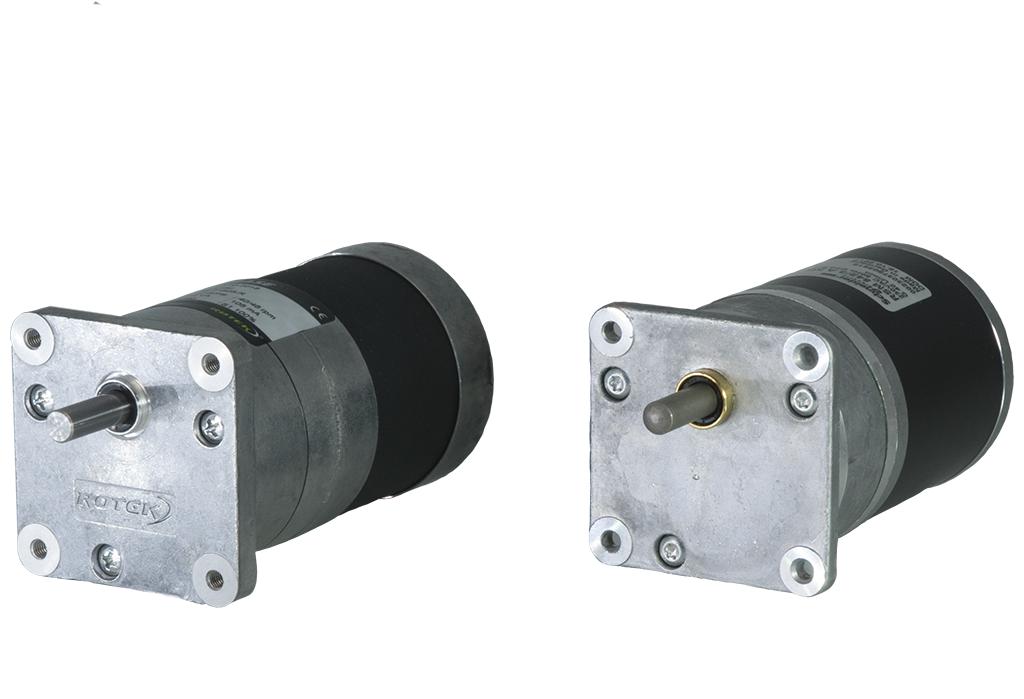

ROBASE and Berger Lahr RSM with spur gears

Rotek also has an identical alternative for the popular Berger Lahr G helical gear series with its G series. Both gears have shaft sealing rings, proven sintered sleeve bearings, lifetime lubrication and are designed for a continuous torque of 6 Nm. However, the Rotek gears permit a considerably higher radial load with 120 N. Rotek has a large range of available transmission ratios in its product portfolio ranging from 5:1 to 1333:1 and also offers enhanced versions of the gear for higher torques.

With a simple adapter and the Rotek type W gear you have the same gear as the Berger Lahr type P gear. We can produce the first gear stage in a strongly attenuating fabric-based laminate for especially noise-sensitive applications. The Berger Lahr motors can best be compared with the Robase.

Motors in the Roslyde or Rosync series may also be advisable depending on the requirements because the customer can take advantage of the special properties of the energy-efficient Rosync or the low-vibration and smooth running Roslyde motor.